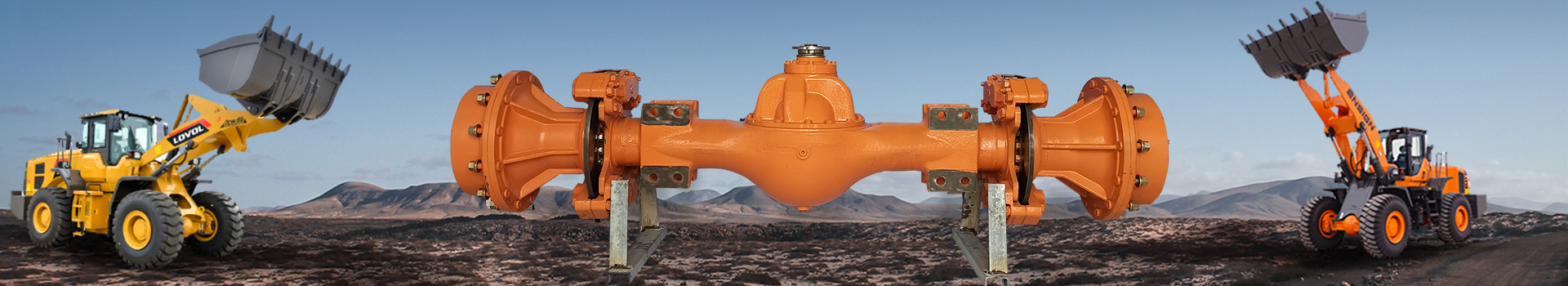

Wheel Loader Ring Gear

1. Host supporting components, original factory quality standards.

2. Selected high-quality steel, wear-resistant and wear-resistant, with a longer service life.

3. Smooth operation, low noise, and excellent reliability performance.

4. Directly supplied by the manufacturer, supporting customized processing according to demand.

5. Outstanding cost-effectiveness and guaranteed quality throughout the entire process.

6. The factory has a constant inventory, and logistics and distribution are fast and efficient

Wheel Loader Ring Gear

The ring gear assembly is an important part of the wheel reducer of 7-ton XCMG wheel loader. By using internal gear transmission to achieve power reduction and steering, the high-speed low torque power output by the engine is converted into low-speed high torque output, achieving efficient power transmission, improving the fuel economy of the entire vehicle, and providing convenience and safety guarantees for the driver.

Feature

1. Calibration and adaptation of original equipment: Strictly follow the technical specifications of XCMG 7-ton loader host, and the installation size and connection interface can be directly assembled by matching the whole machine 1:1.

2. High strength structural design: Made of alloy steel material, processed through forging and carburizing quenching processes, it has excellent impact resistance and wear resistance.

3. Precision transmission optimization: The tooth profile is ground and the meshing clearance is precisely controlled, ensuring smooth and vibration free operation with lower noise levels than industry standards.

4. Flexible customization: supports personalized adjustment of gear tooth profile parameters and size specifications, adapting to drive axles and special operating requirements.

Function

1. Power transmission: As the core transmission component of the drive axle, it transmits power torque to the wheels, providing power for the loader's travel and soil excavation operations.

2. Speed regulation: By optimizing the gear meshing ratio, the reasonable matching of speed and torque can be achieved, meeting the dual requirements of low-speed heavy load and high-speed driving of the loader.

3. Load bearing bracket: It bears the self weight and ground reaction force of the loader during operation, ensuring the overall structural stability of the drive axle and avoiding deformation and damage.

4. Whole machine system protection: It has overload buffering characteristics to reduce the wear risk of other components.

Product Maintenance

During normal operation, the loader should regularly maintain the various components of the drive axle, including cleaning, inspection, and maintenance, to avoid component wear and corrosion. Replace or add lubricating oil appropriately during use to ensure lubrication, reduce wear during gear operation, and avoid rust and corrosion. Regularly check the clearance between gears and ring gears, adjust it in a timely manner, and ensure the accuracy and stability of gear transmission.

Application

1. Infrastructure engineering: suitable for heavy work scenarios such as earthwork excavation and stone transportation in highway construction and bridge construction.

2. Mining: Able to undertake ore loading and short distance transportation tasks in harsh environments such as open-pit mines and quarries.

3. Ports and docks: used for loading, unloading, and stacking of bulk cargo.

4. Agriculture, forestry and water conservancy: suitable for farmland improvement, forestry timber transportation, etc.

5. Factory logistics: Meet the high-frequency and low-intensity operational needs of factories, warehouse material loading and unloading, and site leveling.