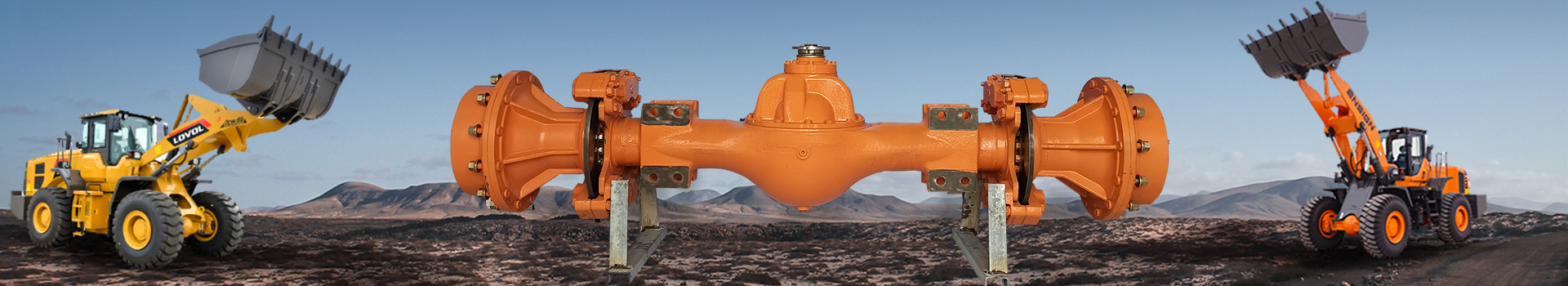

Loader Drive Axle Flange

1. Original high-quality components, XCMG main reduction assembly supporting parts.

2. Made of high-strength steel, it has high tensile strength and compressive performance.

3. Stable operation, good sealing performance, and high structural reliability.

4. Internal casting workshop, supporting customized processing according to technical specifications.

5. Competitive prices and strict quality certification.

6. The factory has sufficient inventory to ensure timely delivery and efficient logistics.

Loader Drive Axle Flange

The flange component of the main reducer is a key connecting component of the rear drive axle of the XCMG wheel loader, mainly used to transmit torque and ensure a stable and firm connection between the main reducer and the drive axle.

The rear axle input flange, rear main reducer housing, main transmission bevel gear pair, differential housing, gears, etc. constitute the rear axle main reducer assembly.

Characteristics

High Strength and Durability: Flanges are typically made from high-strength alloy steels or cast iron to withstand extreme torsional stress, shock loading, and heavy-duty operation in harsh construction environments.

Precision Engineering: They are precision-machined to ensure a perfect fit and reliable integration with other drivetrain components, which minimizes vibration and wear.

Secure Connection: The design involves bolt connections to securely link the components, maintaining alignment and preventing movement under load. O-rings and seals are often used with the flange components to ensure a tight seal, preventing lubricant leakage and contamination.

Corrosion Resistance: The components often feature corrosion-resistant coatings or materials to prevent rust and degradation in humid or chemically aggressive environments, enhancing 。

Application

The main reducer flange is specifically used in the drivetrain system of 7ton XCMG wheel loaders . Its applications are vital to the loader's overall function:

Construction Sites and Mining: It is essential for heavy-duty applications like moving soil, rock, sand, and debris, where high torque and durable power transmission are required.

Material Handling: It enables the loader to perform tasks such as loading dump trucks, excavation, ground leveling, and stacking materials efficiently and reliably.

Off-Road Environments: The robust design is suited for the rugged, off-road conditions typical of construction and industrial sites, providing the necessary strength for operations on uneven or unstable terrain.