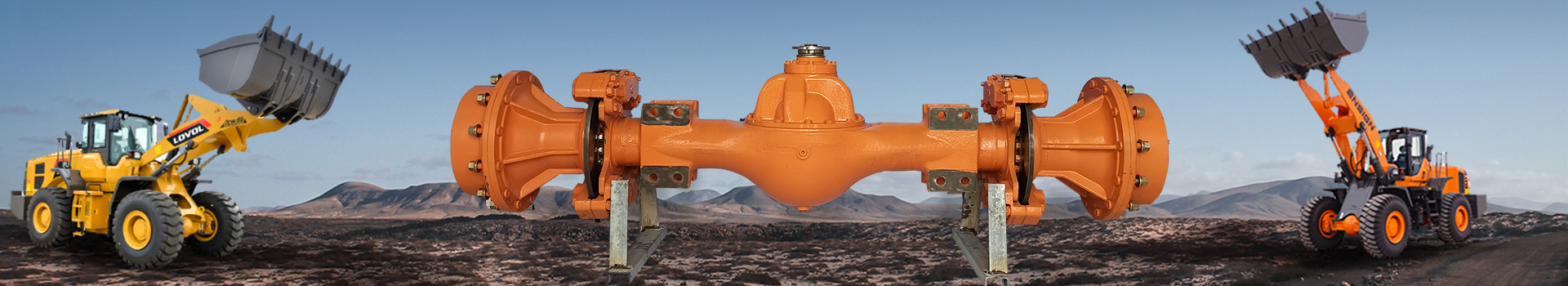

5 Ton Main Reducer Assembly

1.Lovol original specs, standard for 5-ton loader host matching.

2. Industrial-grade steel, wear/impact resistance meets industry standards.

3. Stable operation, low noise, reliable under complex working conditions.

4. Professional workshop production, technical customization supported.

5. Competitive pricing, factory testing system quality certified..

6. Inventory management system, efficient delivery & logistics response.

5 Ton Main Reducer Assembly

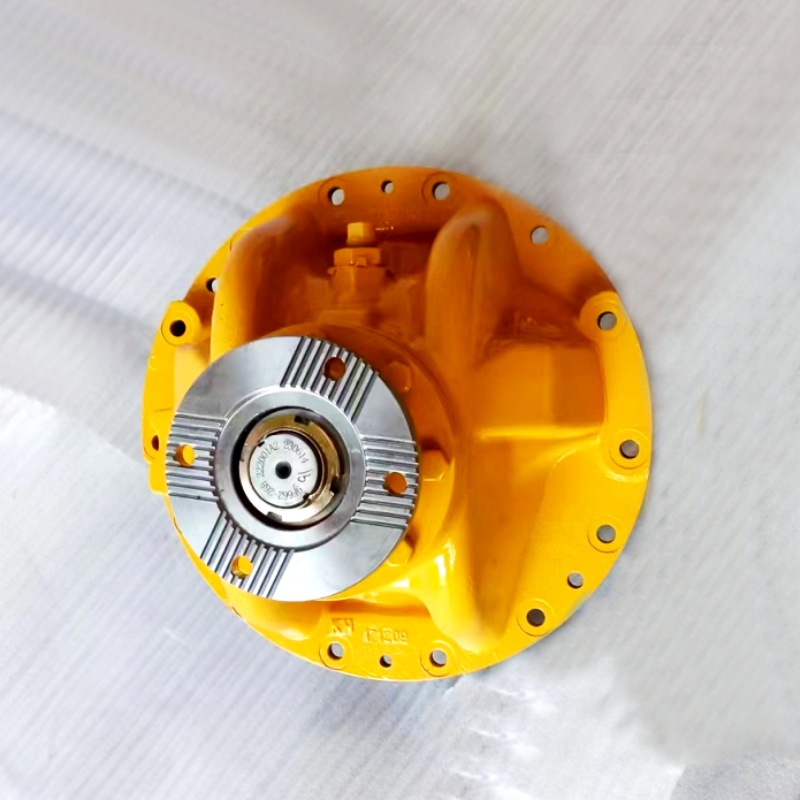

The main reducer assembly is used for the Lovol drive axle of a 5-ton wheel loader in construction machinery. The 9F662 main reducer assembly is used for FL955 and FL956 wheel loaders. The core components of the main reduction assembly include input flange, angular nut, differential assembly, and spiral bevel gear. The differential assembly is composed of differential housing, half shaft gear, planetary bevel gear, cross shaft and other parts, which are precisely matched to complete power transmission and deceleration, ensuring the power output efficiency of the whole machine.

Feature

1. Strong model adaptability, differentiated design of flange specifications, bolt hole sizes, etc., accurately matching the needs of different 5-ton/5.5-ton models.

2. The structure is strengthened and upgraded, and the gears adopt grinding and strong spraying technology, greatly improving their impact resistance and wear resistance.

3. Original factory matching quality, as the core component of Lovol's main models, it has strong compatibility with the whole machine and a large market share, making it convenient to obtain maintenance parts in the future.

Performance

Adopting the gear grinding and strong spraying process, coupled with a reinforced differential, it can adapt to heavy-duty operation requirements and greatly improve stability in complex working conditions; The core gear and housing are made of high-quality steel, which has outstanding wear resistance and impact resistance, and can extend the service life of the components; And the assembly accuracy of each component is high, the power transmission is smooth during operation, which can reduce noise and running jolts, and ensure the efficiency of the whole machine operation.

Application

As a core component of the Lovol 5-ton model with a high market share, it is suitable for various heavy-duty operation scenarios such as mines and construction sites. As an original supporting component, this assembly has guaranteed quality and overall compatibility. At the same time, the market supply is stable, and the circulation of related accessories is strong. It is convenient to obtain accessories for subsequent maintenance and replacement, which can reduce equipment downtime waiting time.

Corporate Strength

Our company has an experienced technical service team and a well-trained professional logistics team, with clear division of labor and close cooperation in all aspects. Real time monitoring of inventory to ensure sufficient goods and accurate data. There are professional technicians in production to inspect and ensure the product qualification rate, greatly improving delivery efficiency. A professional logistics team selects the most suitable transportation method based on customer needs, ensuring timely and accurate delivery of goods to the customer's destination.