The Professional Welding Equipment Of Shandong Zhaokun Engineering Machinery Co., Ltd. Has Enabled Its Products To Reach The Leading Level In The Industry

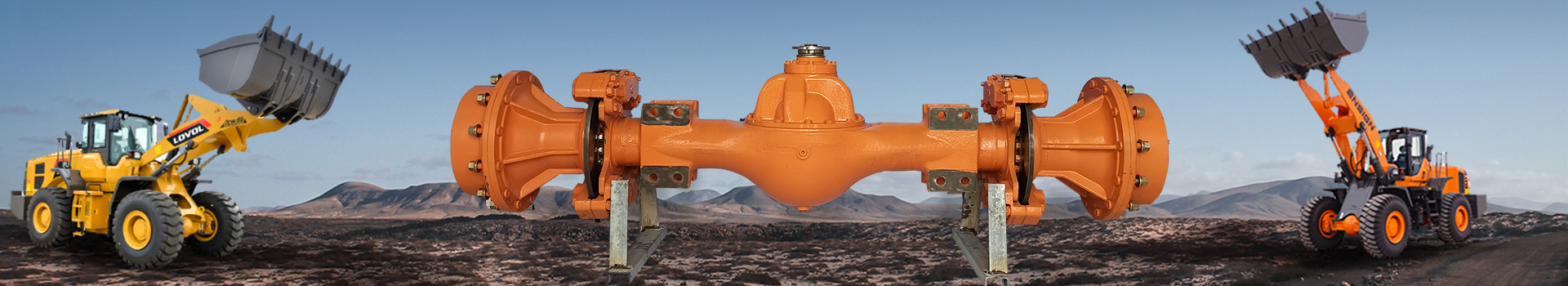

As the core load-bearing component of the wheel loader drive axle, the manufacturing accuracy and quality stability of the axle housing are particularly important. With quality assurance for each component, the welding quality directly affects the safety and durability of the entire vehicle.

To better meet the demands of customers, the company has installed and fabricated specialized welding equipment for axle housings, effectively ensuring the uniformity of weld seams and the consistency of penetration depth, significantly reducing the quality fluctuations caused by manual operation. It has also equipped a dedicated heat preservation pool to carry out standardized post-weld heat treatment processes, which can effectively eliminate residual welding stress, improve the microstructure of the weld zone, and enhance the material's toughness and fatigue resistance. A specialized inspection platform has been provided to conduct comprehensive tests on key technical indicators such as dimensional accuracy and positional tolerance of the axle housing, ensuring that core parameters like the coaxiality of the bearing seat and the straightness of the housing comply with technical requirements. The production of axle housings has achieved significant improvements in process control, consistency of heat treatment, and quality inspection, ensuring that each axle housing product strictly meets the technical standards.

Through the investment in a series of specialized equipment and process optimization, our company's axle housing products have achieved industry-leading standards in strength, precision, and consistency. These products fully meet customers' demands for high-performance and highly reliable drive axle housings, laying a solid foundation for subsequent mass production and market expansion.