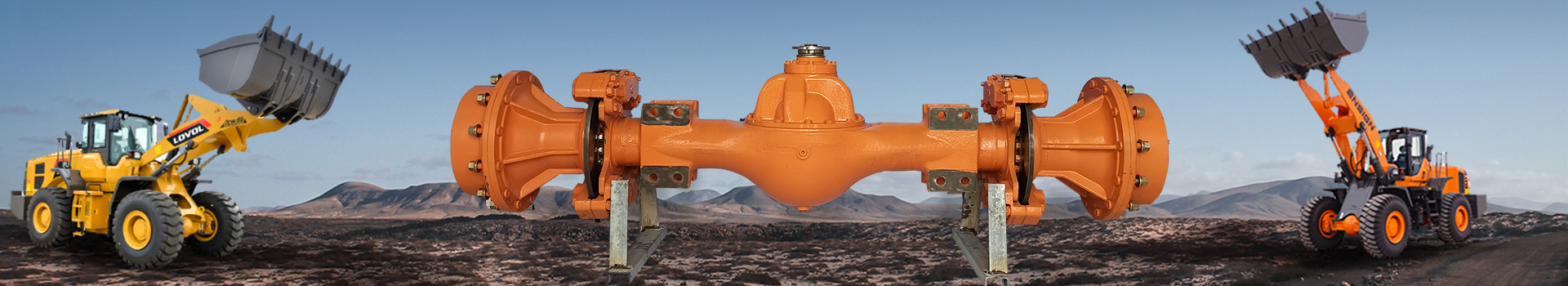

Planetary Carrier Assembly For Loader

1. Genuine-grade replacement parts, fully compatible with main machinery.

2. Constructed from premium steel—wear-resistant, damage-resistant, and long-lasting.

3. Steady operation, low noise output, and exceptional reliability.

4. Factory-owned storefront,custom manufacturing services are supported.

5. Budget-friendly rates paired with strict quality assurance.

6. In-factory stock, with fast & hassle-free shipping and logistics.

Planetary Carrier Assembly For Loader

The planetary carrier assembly in a 5-ton Lovol loader is a critical component of the final drive system(planetary reducer) located within the wheel hubs and the main reducer in the axle. It is engineered for high durability, efficient torque distribution, and reliable performance under heavy-duty conditions.

Characteristics

Robust Construction: The assembly features thick, high-strength plates and reinforced components, designed to handle heavy loads, high torsional torque, and impact forces typical in demanding work environments.

Precision Engineering: Components are manufactured with precision,, ensuring high firmness, compactness, and resistance to distortion.

Even Load Distribution: The planetary design allows for the distribution of engine torque across multiple gear sets, which provides a high torque-to-size ratio and excellent efficiency.

High Reliability: The design and material choices are verified through extensive testing to ensure reliable operation under tough conditions.

Function

Torque Multiplication and Speed Reduction: The primary function is to provide a final stage of gear reduction, multiplying the torque from the transmission and delivering it to the wheels at a reduced, usable speed.

Power Transmission: It efficiently transmits engine power from the drive axle input shaft to the wheels, enabling movement and traction.

Support and Stability: The assembly is integral to the axle and wheel hub structure, helping to support the weight of the loader and its substantial load while ensuring stable operation.

Differential Action Support : The planetary final drives work in conjunction with the main differential to allow wheels to turn at different speeds during turns, improving maneuverability and reducing tire wear.

Product Maintenance

Regular inspection and replacement of hydraulic oil and engine oil can prevent oil deterioration, thereby protecting the normal operation of the engine and hydraulic system.Reasonable tire pressure can reduce fuel consumption, avoid uneven wear, and enhance the driving stability of loaders. After the loader is in operation, the body and components should be cleaned in a timely manner to prevent the accumulation of soil and impurities. It can effectively extend the service life of the loader and improve its work efficiency.

Application

The planetary gear frame assembly is applied as a critical component in the final drive system of Lovol 5-ton wheel loaders . These loaders are primarily used in:

Construction Sites: For moving materials like soil, gravel, and sand.

Mining and Quarrying: Handling heavy-duty tasks with abrasive materials like rock and ore.

Material Handling: Loading and unloading various materials in applications such as ports, manufacturing plants, and large farms.

Infrastructure Projects: Working on roads, bridges, and other large-scale engineering projects.