3-Ton Planetary Gear

1. Original quality parts, host supporting products.

2. Adopting high quality steel, wear-resisting and anti-manufacturing, prolonging the use of time.

3. Smooth running, low noise, high reliability.

4. Factory shop, support processing customization.

5. Affordable price, quality assurance.

6. Factory storage, delivery, transport, convenient and quick.

3-Ton Planetary Gear

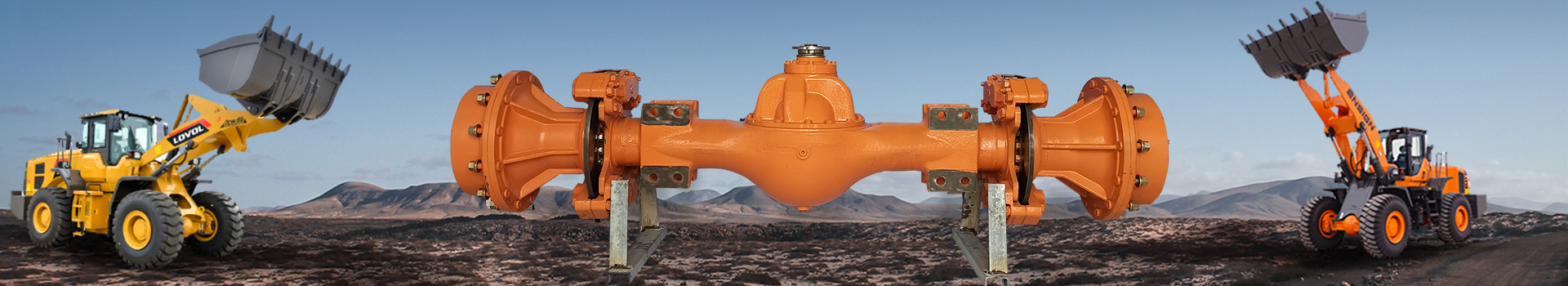

The planetary gear is the core component of the planetary carrier in the drive axle of the XCMG Meichi 3-ton wheel loader. The gear has 15 teeth and a thickness of 52mm. It does not work independently, but as a member of the "planetary gear" group in the planetary gear mechanism, it plays a key role in power conversion and enhancement in the wheel side reducer.

Its core function is to achieve power distribution, torque increase and deceleration, and load bearing. After the power is input from the sun gear, it is evenly distributed to several planetary gears, achieving efficient distribution and convergence of power. Its specific gear ratio, combined with the sun gear and ring gear, forms a huge transmission ratio, converting the input high-speed low torque power into the low-speed high torque required by the driving wheels, providing crucial traction and digging force for the loader. The astonishing thickness of 52mm endows it with extremely high bending and impact resistance, which can reliably withstand extreme heavy loads and severe impacts during operation, ensuring the durability of the entire drive axle.

Application Scenario:

This gear is specifically designed for the wheel reducer of a 3-ton wheel loader. Its application scenario is: power is distributed to the half shaft through the main reducer and differential, and finally transmitted to the planetary reduction mechanism inside the wheel hub. Here, the planetary mechanism completes the final deceleration and directly drives the wheels, reducing the ground clearance of the bridge deck, thereby significantly improving the passability, stability, and operational reliability of the loader in harsh working conditions such as mines and construction sites.