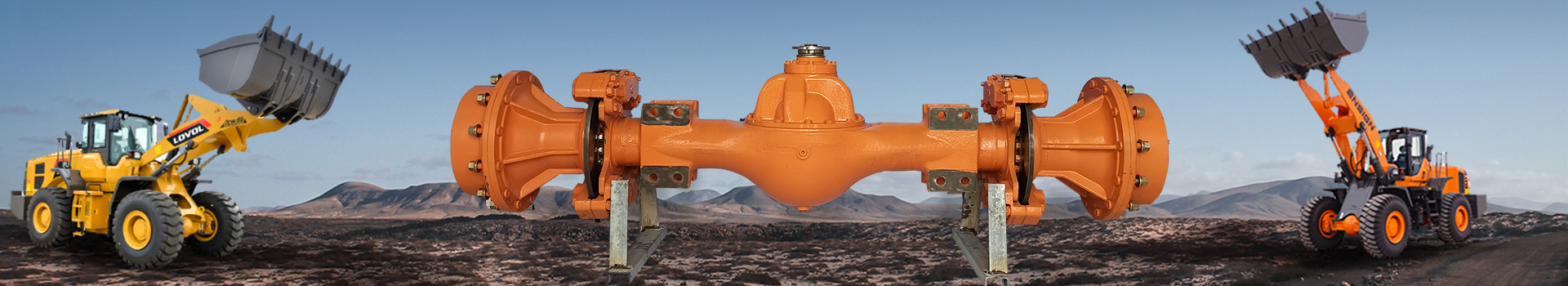

Wheel Loader Axle Spiral Bevel Gear

1. OEM - grade components, perfectly matching the Main reducer assembly .

2. With excellent wear resistance and impact resistance, extending service life.

3. Stable meshing, low vibration, and high transmission efficiency.

4. Factory - direct production, supporting customized processing according to drawings.

5. Competitive price, with strict quality inspection to ensure reliability.

6. Factory - based warehousing and logistics, ensuring fast delivery and convenient transportation.

Wheel Loader Axle Spiral Bevel Gear

Spiral bevel gear is an important component in the drive axle transmission system of the 7-ton XCMG wheel loader. The gear pair ensures effective torque transmission from the gearbox to the wheels. Their design enables them to operate smoothly and quietly under high loads, making durability and performance crucial in harsh environments.

The gear pair consists of 9/43 teeth, 26 keys, an inner diameter of 220.5mm, and an outer diameter of 412mm. Together with the flange, differential assembly, main reducer housing, bearings, bolts, etc., it forms the main reducer assembly of the XCMG loader drive axle.

Features And Performance

Heavy duty design: Spiral bevel gears are part of XCMG's "ultra heavy" structure, capable of withstanding heavy loads and harsh conditions without premature failure.

High strength and wear resistance: The gear pair is made of optimized materials and undergoes special heat treatment processes to improve reliability, wear resistance, and impact resistance.

Optimization of meshing: This design focuses on appropriate gear meshing clearance to ensure smooth and quiet operation, while minimizing abnormal sounds and wear to the greatest extent possible.

Enhanced torque capability: Structural and material upgrades ensure high driving capability, and the torque transmission of all gears is enhanced, improving overall machine performance.

Application

The XCMG loader equipped with sturdy spiral bevel gears is suitable for various heavy material handling and earthwork operations:

Construction site: general earthwork, excavation, and material loading.

Mining and port logistics: handling bulk materials such as coal, ore, and aggregates under harsh working conditions.

Storage: Efficient movement and stacking of materials.

Various conditions: The robustness of the gears enables the loader to operate reliably in various harsh environments, including bumpy roads or dusty conditions.

Corporate Strength

Our company has professional technical personnel, after-sales service team, and cooperates with multiple well-known logistics companies to match the best logistics company for the transportation of goods according to customer order requirements. At the same time, logistics personnel track logistics company information, promptly contact and handle any special issues, and ensure that the goods arrive at the customer's designated location on time. The company provides product technical support to customers to achieve customer satisfaction.