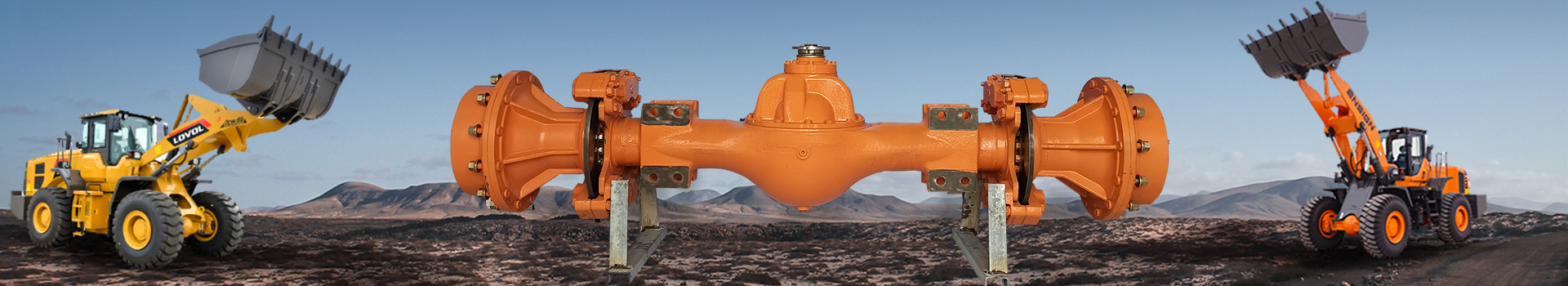

Loader Main Crown Wheel Pinion Gear

1.Premium genuine components, perfectly matched with main equipment assemblies.

2.Manufactured with high-grade steel, featuring excellent wear resistance and durability, effectively extending service life.

3.Stable and smooth operation, low noise emission, and outstanding reliability.

4.Direct from factory, supporting customized processing and tailored solutions.

5.Cost-effective pricing with strict quality assurance.

6.Adequate factory inventory, efficient logistics and delivery, ensuring fast and convenient shipment.

Loader Main Crown Wheel Pinion Gear

The active and driven spiral bevel gears (commonly known as crown wheels and small gears) model 9F662 are the core components of the front axle transmission system of the LOVOL5 ton wheel loader. This gear pair is mainly responsible for changing the direction of power transmission, reducing speed and increasing torque, smoothly transmitting the power of the gearbox to the driving wheels, and achieving the forward, backward, and steering actions of the loader. Its structural design features high load-bearing capacity, smooth transmission, good wear resistance, high efficiency, and excellent impact resistance, making it a key foundational component for ensuring the heavy-duty operation and reliable driving of loaders.

For the heavy-duty operation conditions of LOVOL 5-ton wheel loader (such as material shoveling, transportation, lifting, etc.), the 9F662 main and driven spiral bevel gears have been optimized in terms of structural design and performance calibration. They have three core characteristics: high load-bearing capacity, smooth transmission, wear resistance, high transmission efficiency, and excellent impact resistance. Firstly, the high load-bearing capacity relies on high-strength gear blanks and reasonable tooth profile design, which can withstand the high torque and high load impact during the loader's heavy-duty operation, avoiding gear deformation or fracture; Secondly, the arc-shaped tooth surface meshing method of spiral bevel gears is gradual in and gradual out meshing, with a large contact area and uniform force during the meshing process. Compared with straight bevel gears, the transmission process has no obvious impact and lower noise, achieving smooth transmission and adapting to the frequent start stop and variable speed operation requirements of loaders; Thirdly, the optimized tooth profile parameters and meshing clearance design reduce energy loss during the transmission process, maintain high transmission efficiency, effectively reduce fuel consumption, and improve the operating efficiency of the loader.

During the assembly of the entire machine, it is necessary to accurately adjust the meshing clearance and meshing marks. In daily use and maintenance, it is necessary to regularly check the gear status and timely supplement special lubricating oil to ensure its stable operation, thereby supporting the heavy-duty operation requirements and driving reliability of the LOVOL 5-ton 9F662 wheel loader.

Company Services

There are various models and brands of loader accessories in the company. The staff determines the product code and matches the products based on the order information. After verifying and inspecting each product, assembly, testing, packaging, and labeling are carried out. Professional personnel will contact logistics for delivery and track logistics information to promptly address any issues and ensure timely delivery of goods. Technicians provide professional technical services to customers to ensure their satisfaction.