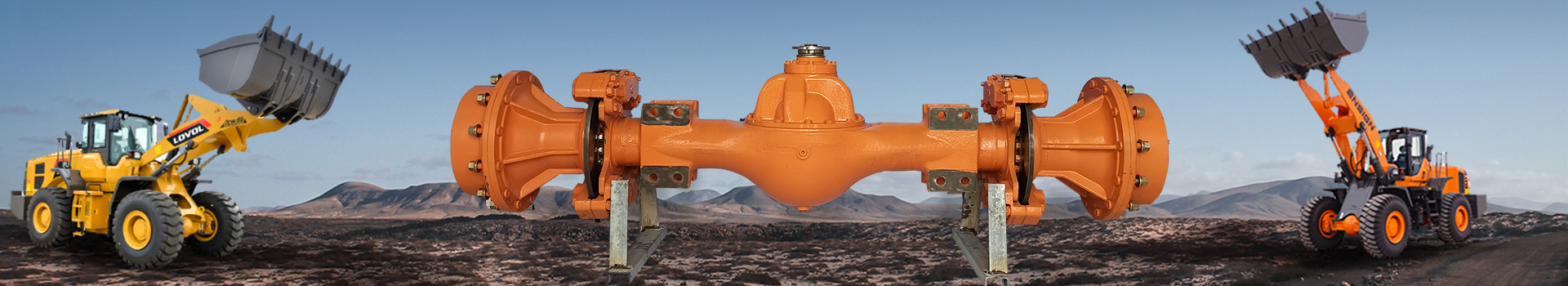

7 Ton Main Reducer Differential Assy

1. Genuine Lovol parts supplied directly by the factory, perfectly matching the host adaptation needs of 7-ton loaders.

2. Forged from high-grade steel, with superior wear and impact resistance, greatly extending the service cycle of the differential.

3. Quiet and smooth operation, stable performance in heavy-duty operations, making equipment operation more worry-free.

4. Manufactured directly by the factory, supporting exclusive customization to meet the adaptation needs of different models.

5. Cost-effective pricing with strict quality control at all levels and worry-free after-sales service.

6. Factory direct shipping from stock, efficient logistics, and no waiting for supply.

7 Ton Main Reducer Differential Assy

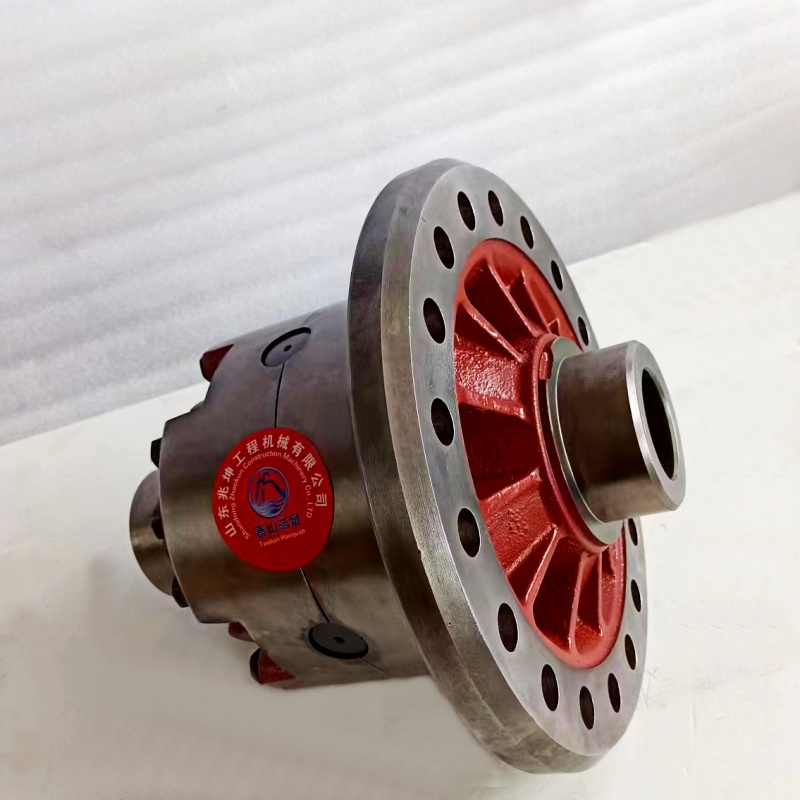

The differential assembly is an accessory of the Lovol front drive axle reducer assembly for a 7-ton construction machinery wheel loader. Composed of differential housing, half shaft gear, bevel gear, axis, cushion pad, etc. Applicable to FL966 FL968 FL970 FL975 FL976 drive axle main reducer assembly accessories. The differential assembly is made of high wear-resistant materials, with low noise and excellent performance, and is a supporting product for the factory's main engine.

Feature

The differential assembly, as a key component of the loader transmission system, directly affects the off-road capability, handling stability, and service life of the vehicle. For a 7-ton Lovol loader, the characteristics of the differential assembly are:

1. Structural reliability: The differential is composed of core components such as the differential housing, planetary gears, and planetary gear shafts. The planetary gears are loosely fitted onto the planetary gear shafts, allowing for self rotation and orbital motion, ensuring differential action between the left and right drive wheels during turning.

2. Sealing and durability: The assembly adopts an optimized sealing structure, which can effectively prevent impurities such as dust and mud from entering, adapt to harsh working conditions, reduce wear and extend maintenance cycles.

3. Load bearing capacity and compatibility: In response to the heavy load operation requirements of a 7-ton loader, the differential assembly adopts high-strength gear materials and wear-resistant processes to ensure stable operation under high torque transmission.

Functions

It can not only stably distribute the power transmitted from the main reducer to the left and right half shafts to ensure the normal driving of the loader, but also allow the left and right drive wheels to rotate at different speeds when the loader operates on turning or uneven roads, avoiding sliding friction between the wheels and the ground and reducing tire wear. Meanwhile, its stable power transmission performance can also reduce the impact on other transmission components such as the gearbox, ensuring the overall operation efficiency of the machine and reducing downtime for maintenance.

Application

As a core supporting component for the drive axle of Lovol 7-ton loaders, main reducer differential assembly is often used for original equipment assembly and maintenance replacement of loaders of the same tonnage of Lovol brand, and can also be compatible with the adaptation requirements of engineering loaders of the same specification of brands such as XCMG. It is widely applied in heavy-duty operation scenarios including mining, infrastructure construction and port loading and unloading, and can cope with various harsh road conditions such as complex rough and muddy roads.