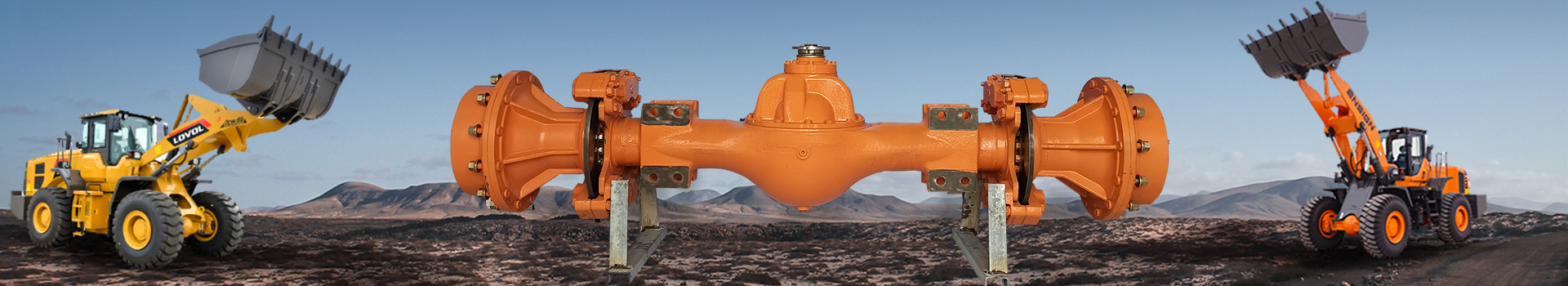

5Ton JC Planetary Gears

1. Original high-quality accessories, specially tailored for host devices, with outstanding adaptability.

2. The product is made of high-quality steel with exquisite craftsmanship, which is wear-resistant and durable, effectively extending its service life.

3. Smooth and quiet operation, lower noise, strong reliability, can ensure the continuous and efficient operation of the equipment.

4. It also supports on-demand customization, flexibly adapting to various processing scenarios and different needs.

5. The product has reasonable pricing, reliable quality, and excellent cost-effectiveness.

6. We also provide professional warehousing, efficient distribution, and full transportation services to ensure fast, convenient, and timely delivery of goods, fully meeting your usage needs.

5Ton JC Planetary Gears

The 5-ton Jincheng (JC) planetary gear is the core component of the differential assembly of the wheel loader drive axle, consisting of a cross shaft, half shaft gear, planetary gear, and special gasket. The bevel gear structure is linked by a cross axis to achieve differential transmission between the left and right axles: when the loader turns, the resistance of the inner wheels increases, and the planetary gears rotate to drive the outer wheels to accelerate, eliminating tire slippage and ensuring smooth steering. This component is compatible with 5-ton loaders such as Lovol, Yingxuan, Shantui, Doosan, and Degong, with strong compatibility.

Attention should be paid during maintenance: the meshing clearance between the planetary gear and the half shaft gear should be precisely adjusted through shims (tolerance ± 0.02mm) to avoid abnormal noise; Cross axis carburizing and quenching treatment, high wear resistance; It is recommended to prioritize the use of original parts in high load conditions such as mines to ensure transmission reliability.

The Application Of The Product

The differential bevel gear automatically adjusts the speed difference between the left and right wheels through the rotation and revolution of the planetary gear when the loader is turning, ensuring reasonable power distribution and avoiding tire slippage and wear. This can significantly improve operational efficiency and stability, reduce power loss, and ensure smooth and safe heavy-duty operations when frequently turning in narrow areas such as mines and storage yards.

To ensure the assembly accuracy of the differential bevel gear, the key is to accurately adjust the gear mesh clearance and mesh marks, which is the core to ensure smooth transmission, reduce wear and noise.