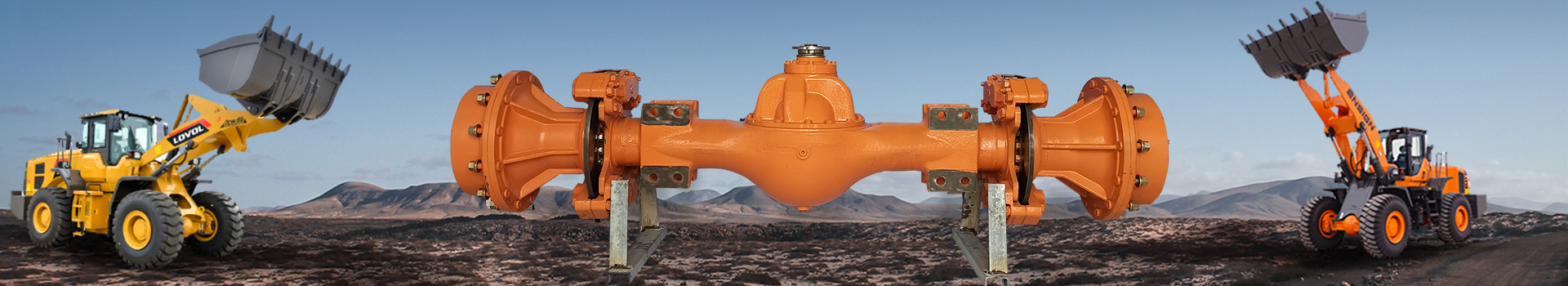

Loader Drive Rear Crown Wheel /Pinion

1. Authentic-quality components, engineered to match original equipment specifications.

2. Constructed from premium alloy steel—boasting superior wear resistance and long-lasting durability.

3. Consistent, low-noise operation paired with top-tier operational dependability.

4. Direct-from-manufacturer supply, with tailored production options to meet your needs.

5. Budget-friendly pricing backed by rigorous quality assurance standards.

6. Ready inventory, prompt delivery, and hassle-free logistics support.

Loader Drive Rear Crown Wheel /Pinion

The main (pinion) and driven (ring) gears in a 3-ton loader's drive axle are typically high-strength spiral bevel gears designed to transmit high torque, reduce speed, and change the power direction efficiently and quietly.

The gear pair is a component of the main reducer assembly of the 3-ton Yunyu drive axle of a wheel loader, with an outer diameter of 381.3mm, an inner diameter of 234.2mm, and 18 keys. The main reducer assembly is composed of the main reducer shell, differential, flange components, bearings, etc.

Performance

High Load Capacity: The design distributes the load across a larger contact surface, enabling them to handle significant torque and shock resistance typical in loader operations.

Smooth & Quiet Operation: Gradual engagement of teeth significantly reduces noise , improving operator comfort and machine longevity.

Durability and Reliability: Engineered materials and robust design provide long life and dependable operation in harsh working environments.

Efficiency: They offer high transmission efficiency, though the inherent friction generates some heat that requires proper lubrication.

Application

Gear pairs are mainly used for the main reduction transmission of drive shafts in construction equipment. They can handle high-speed and high load power transmission quietly, and are often used for loading and unloading farm feed. Construction projects involve transportation, transfer, and other working conditions.

Service Capability

Our team efficiently allocates products based on detailed customer order information, conducts quality inspections, and carries out meticulous packaging, labeling, and identification coding. We select the best logistics supplier based on the delivery address, track the shipment status in real-time, and ensure timely and accurate delivery of goods to customers.