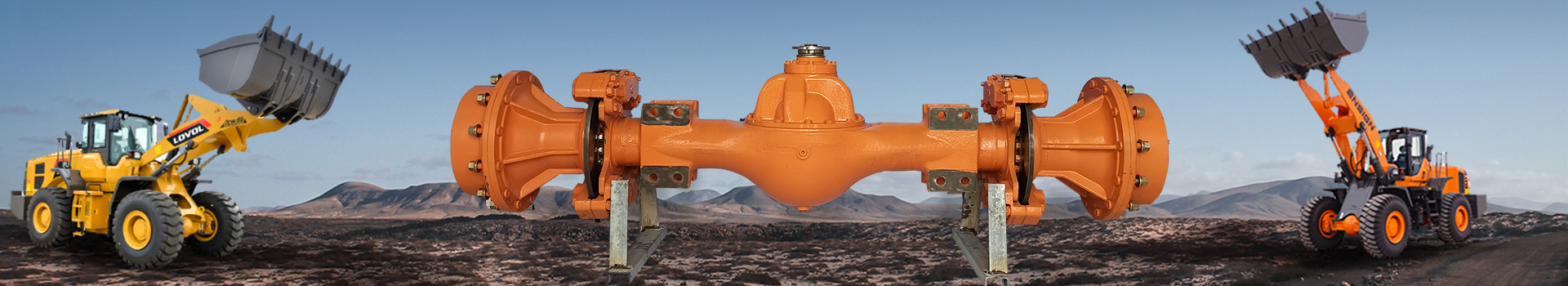

Loader Axle Part Gear Pair

1. Original quality gear pair components, matching Lovol 5-ton host supporting standards.

2. Adopting high-grade alloy steel, excellent wear resistance and anti-deformation performance, effectively extending service life.

3. Precise meshing, smooth operation, low noise and high transmission reliability.

4. Factory direct supply, supporting customized processing of Lovol 5-ton gear pair specifications.

5. Cost-effective pricing with strict quality inspection and assurance.

6. Professional factory inventory, fast delivery and convenient transportation.

Loader Axle Part Gear Pair

The gear pair in the drive axle of the Lovol 5-ton loader is the core component of the main transmission system, and its design directly affects the overall performance of the drive axle.

The gear pair, differential assembly, main reducer housing, flange and other components constitute the 9F662 loader main reducer assembly.

The master-slave spiral bevel gear pair is coded as 9F662-26B222001A2, with a specification of 8:37 teeth and 45 keys, and is used for the 9F662 model loader. It mainly functions to slow down and transmit power. It drives the passive bevel gear through the active bevel gear, achieving deceleration and power transmission.

Performance

High load-bearing capacity: The contact area of the helical teeth is large, which can withstand large radial and axial loads, suitable for transmitting high torque, and meets the power requirements of the loader under heavy load operations.

Transmission smoothness and low noise: The progressive meshing characteristics reduce the impact and vibration during operation, making the transmission process smoother, with lower noise levels, and improving operational comfort.

High transmission efficiency: The rolling meshing method reduces the sliding friction of the tooth surface, improves mechanical efficiency, and helps reduce energy loss.

Structural reliability: Variants such as spiral bevel gears have the characteristics of compact structure, wear resistance, and long service life, which are suitable for frequent start stop and impact load conditions of loaders

Function

In the drive axle, the helical gear pair mainly undertakes the following functions:

1. Change the transmission direction: Convert the longitudinal rotational motion input by the gearbox into vertical lateral motion to drive the wheels to rotate.

2. Deceleration and torque increase: By reducing the transmission ratio of the gear pair, the speed is reduced while increasing the torque output to meet the traction requirements of the loader in complex terrain.

3. Implement differential function: Work in conjunction with the differential to distribute torque at different speeds of the left and right wheels, ensuring steering stability.

4. Load bearing and support: As a structural component of the drive axle, it bears vertical and longitudinal forces from the road surface and provides an assembly foundation for the half shaft and other components.

Application

The application of helical gear pairs in the drive axle of Lovol 5-ton loader 9F662 needs to match its typical working conditions:

High load adaptability: Suitable for heavy-duty operations of 5-ton loaders, such as material handling and traction tasks, its high load-bearing capacity can cope with frequent impact loads.

Complex terrain adaptation: The transmission smoothness and impact resistance characteristics ensure its reliability on uneven road surfaces or frequent start stop conditions.

Efficiency and lifespan balance: High transmission efficiency helps reduce fuel consumption, while wear resistance reduces maintenance frequency, meeting the economic requirements of construction machinery.

Structural integration: The compact design of the spiral bevel gear saves space on the drive axle, making it easy to integrate with components such as wheel reducers and optimize the overall layout.

Product Maintenance

It is very important to regularly and meticulously maintain and upkeep each component according to the loader instructions during the use of the loader. When stepping on the accelerator to climb or accelerate, if you hear a buzzing sound, it may be due to incorrect meshing markings between the active bevel gear and the passive bevel gear, and it needs to be replaced. Similarly, the sound heard during braking may also be due to meshing issues, requiring gear replacement. At the same time, check the engine oil on time and add or replace it promptly. Beneficial for improving the efficiency of loader operation.