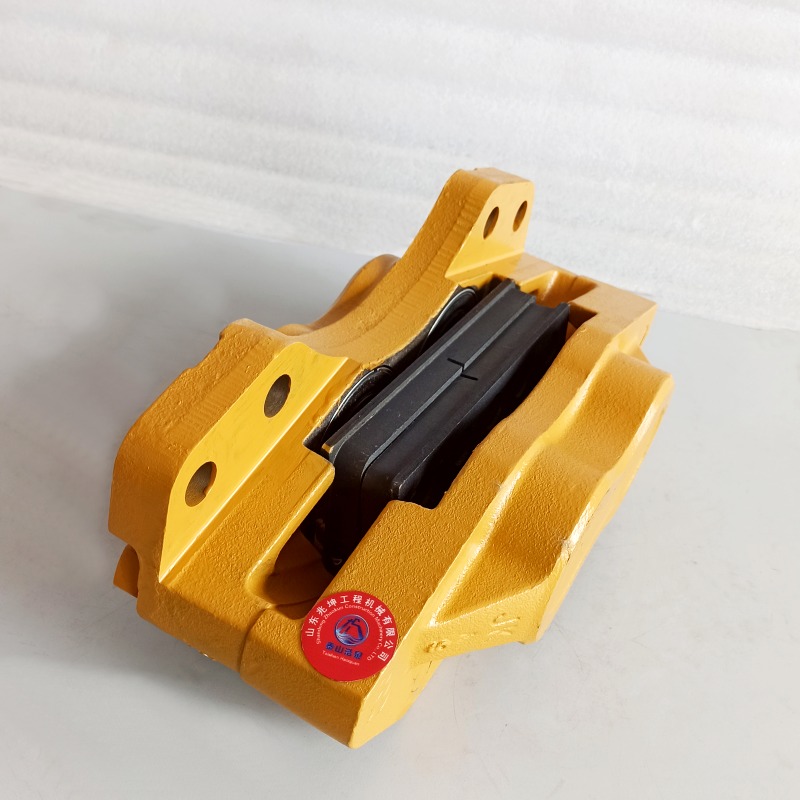

Brake Caliper Of Loader Part

1. Original quality components, perfectly matching the loader's braking system.

2. High wear resistance and strong corrosion resistance, long service life, and improved efficiency.

3. Stable braking performance, low noise, and high safety.

4. Directly supplied from the factory, supporting customized processing as per requirements.

5. Cost - effective price with strict quality control.

6. Sufficient factory inventory, ensuring fast delivery and transportation.

Brake Caliper Of Loader Part

XCMA brake calipers are integral to the braking systems of wheel loaders and are primarily used in applications that demand high load capacity and reliable operation in challenging environments.

The brake assembly has excellent performance and is composed of components such as fixtures, pistons, and brake pads. The brake caliper clamps the brake disc to brake the wheels of the loader, thereby generating friction.

Characteristics

Construction: Most XCMA calipers are made from robust cast iron or forged steel, chosen for its high durability, structural strength, and resistance to deformation under extreme heat and pressure typical in heavy machinery operations.

Actuation: The calipers are part of an air-hydraulic actuated system where pneumatic pressure assists the hydraulic system to apply force, ensuring sufficient clamping power for heavy loads.

Durability : The designs often feature enhanced cooling mechanisms and sealed piston designs to prevent contamination from dust, mud, and moisture common in construction and mining sites.

Product Performance

Made of high-quality materials, it has good wear resistance and corrosion resistance, and can work reliably for a long time. The braking response speed is fast, which can effectively reduce the braking distance and improve the handling of the loader. At the same time, the good heat dissipation design ensures that the brake caliper will not overheat during frequent braking, prolonging the service life.

Application

Construction Sites: Used in frequent stop-and-go operations when moving materials like soil, gravel, and sand.

Mining and Quarrying: Essential for safe operation on steep grades and rugged terrain while hauling heavy loads, where braking systems are under immense stress.

Material Handling: Applied in ports and industrial settings for consistent performance during repetitive loading and unloading tasks.

Agriculture: Used on large farms for various tasks, ensuring stable braking in muddy or uneven field conditions.

Demolition: Provides the necessary control and stopping power for handling heavy debris and operating in high-stress situations.