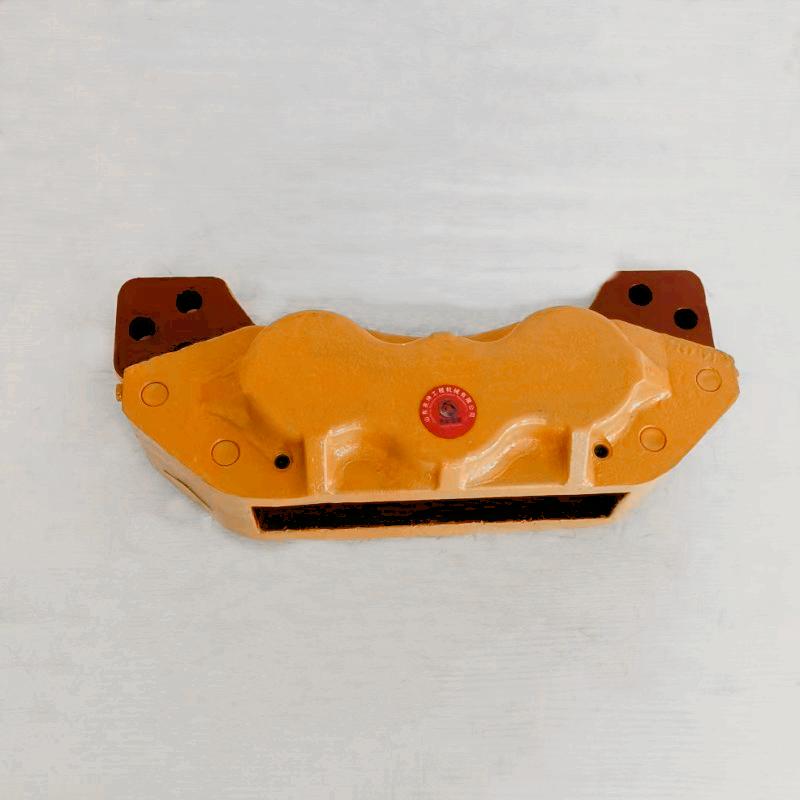

8-Ton Loader Brake Caliper

1. Original quality components,precise fit with Lovol 8-ton equipment, easy installation and replacement..

2. Made of high-grade alloy steel, wear-resistant and anti-corrosive, extending service life significantly.

3. Stable braking performance, low operating noise, strong pressure resistance and long-term stable operation.

4. Factory direct supply, supporting customized processing for special working conditions.

5. Cost-effective pricing with strict quality inspection and assurance.

6. Sufficient factory stock, fast delivery and transportation with convenient logistics.

8-Ton Loader Brake Caliper

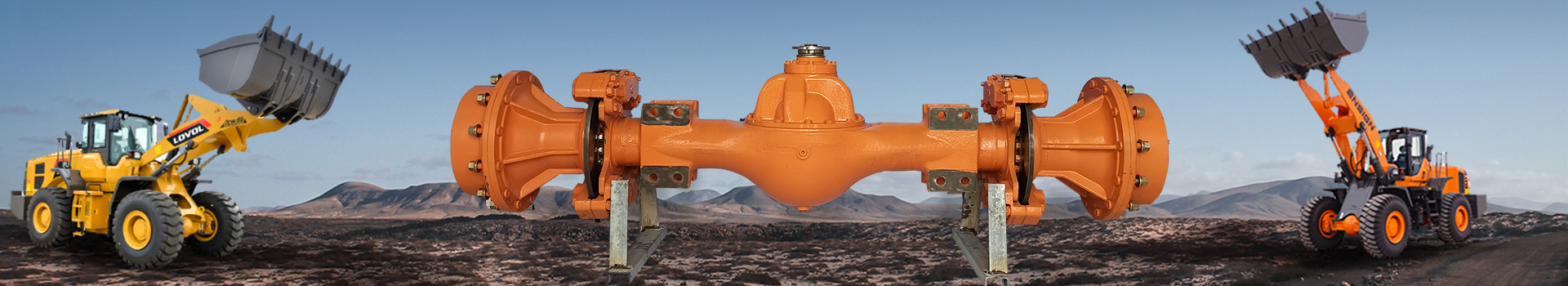

Brake calipers for 8-ton loaders are typically heavy-duty, cast iron units designed to provide reliable, high-force stopping power in demanding industrial environments. They function primarily via a hydraulic or air-over-hydraulic disc brake system and are critical for the safe operation of the equipment.

The brake caliper and brake disc, planetary reducer assembly, main reducer assembly, half shaft, etc. make up the Lovol drive axle assembly。Performance

High Braking Force: Engineered to generate high forces essential for stopping heavy loads and managing the machine's momentum.

Heat Resistance: Designed to operate effectively under high thermal loads generated during continuous braking cycles in applications like downhill hauls or stop-and-go operations.

Fade Resistance: Provide stable and consistent braking performance, even when hot or exposed to mud and water.

Durability: Offer long service life under stress due to their heavy-duty construction and design features.

Function

The primary function of the brake caliper is to halt or slow the loader by creating friction.

Actuation: When the operator applies the brake pedal, compressed air or hydraulic fluid is sent to the caliper's piston chamber.

Clamping: The piston pushes the high-friction brake pads against the rotating brake disc .

Friction Generation: The resulting friction converts the loader's kinetic energy into heat, slowing the wheel's rotation.

Control: This mechanism provides precise control for maneuvering, positioning, and safely stopping the machine, especially on inclines.

Application

8-ton loader brake calipers are used in wheel loaders across a variety of demanding industries:

Construction: General building and road construction, moving materials like soil, gravel, and concrete.

Mining and Quarrying: Handling heavy, dense materials like rock and ore in harsh, abrasive environments.

Waste Management: Used in waste transfer stations and recycling centers, requiring resistance to corrosive materials.

Ports & Logistics: For material handling equipment moving heavy cargo and containers

Product Maintenance

During the operation of the loader, if the braking weakens, the braking system should be checked in a timely manner. For brake calipers, it is necessary to observe whether there are obvious cracks, deformations, or wear on their appearance. Check if the piston of the brake caliper is flexible. It can be determined by manually pressing the piston and observing its return. Use specialized tools to check the gap between the brake caliper and brake disc, and adjust the gap to a reasonable value. If any abnormal situation is found, the brake caliper should be replaced in a timely manner.