Wheel Loader Parts Brake Pad

1. Original equipment manufacturer standard, perfectly matching the brake caliper.

2. Crafted from advanced composite materials, featuring excellent heat resistance and friction property.

3. Rtable braking, long service life, and strong adaptability to various working conditions.

4. Professional R&D team, capable of providing customized solutions for special needs.

5. Competitive price with strict quality control throughout the production process.

6. Efficient logistics system, ensuring timely supply and quick after-sales response.

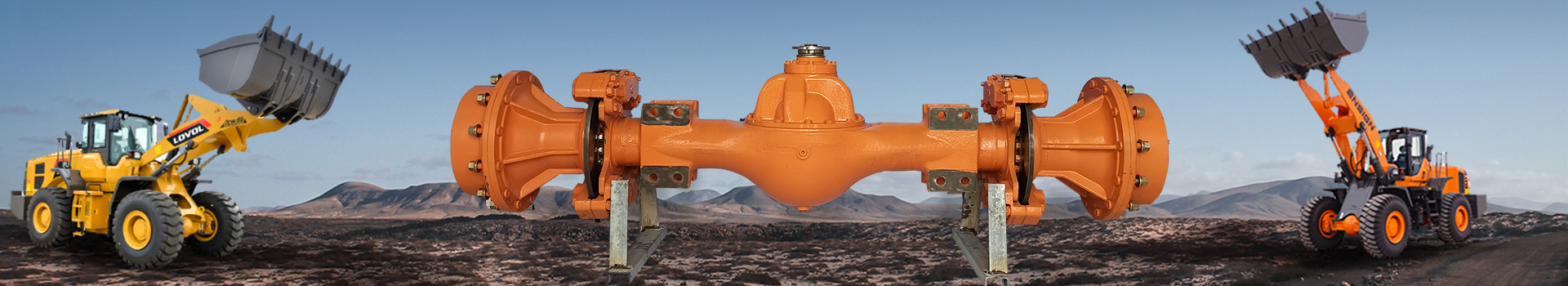

Brake pads are mainly used for the drive axle brake caliper components of the 5-ton LG wheel loader in construction machinery. The brake pads are made of high-quality and wear-resistant materials, with stable deceleration and braking performance, ensuring safe and efficient operation of the machine under various working conditions.

Feature

1.High heat resistance: able to withstand and dissipate a large amount of heat generated during the braking process, thereby preventing brake degradation and system failure.

2.High mechanical strength: They have high shear strength, compressive strength, and hardness, which can resist wear and withstand large loads from heavy vehicles.

3.Wear resistance: The design of brake pads can resist wear even at high speeds and heavy loads.

4.Consistent coefficient of friction: A stable coefficient of friction ensures reliable braking capability at different temperatures, pressures, and speeds.

Performance

1.Excellent braking capability: They provide strong initial engagement and high torque, effectively slowing down heavy loads.

2.Stability: Due to excellent thermal stability and heat dissipation, the performance remains consistent even during frequent and intense braking processes, ensuring consistent braking stability,

3.Durability: Durable materials can reduce wear rates, which is crucial for minimizing maintenance downtime in industrial environments.

4.Full condition reliability: Their design can operate reliably under various working temperatures and environmental conditions, such as humidity, dirt, and dust.

Product Application

The loader mainly relies on the frictional force between the friction plate and the brake disc to achieve braking effect. When the driver operates the brake pedal, the brake generates braking force through the hydraulic system, causing the loader to slow down or stop. primarily for construction, mining, and material handling tasks such as moving soil, loading trucks, and transporting materials.