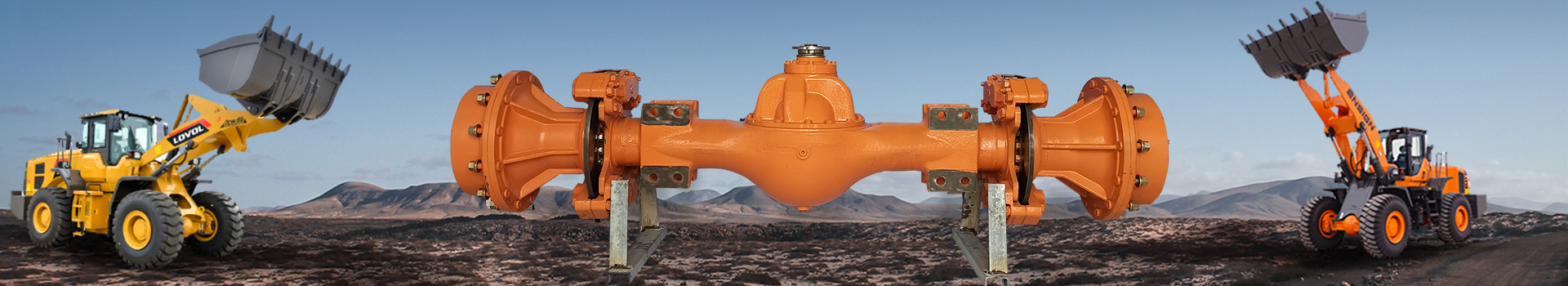

Wheel Loader Parts Brake Caliper

1. Original factory grade parts can be directly used as supporting components for loaders.

2. Made of high-quality steel, it has wear-resistant and durable characteristics.

3. The work runs smoothly, with low noise, reliability, and strong stability.

4. Directly sold by the factory and can be customized according to demand.

5. Low cost while ensuring quality standards and quality assurance.

6. The factory has its own inventory, efficient shipping and transportation processes, and fast delivery speed.

Wheel Loader Parts Brake Caliper

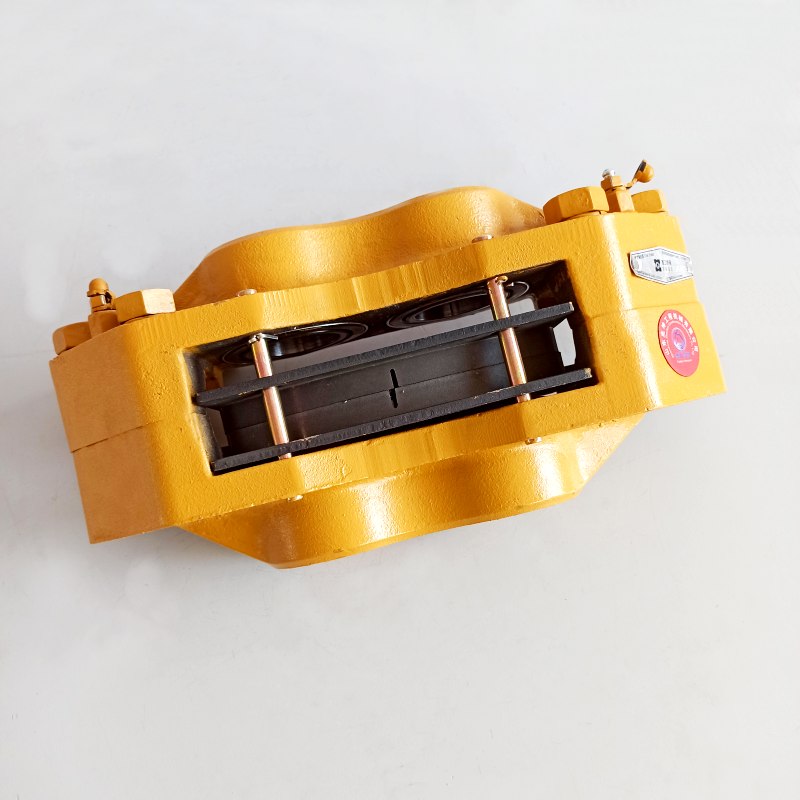

The brake caliper of the loader is the core component of the 3-ton Yunyu drive axle braking system, mainly used to push the brake pads and brake discs to friction through hydraulic pressure, achieving deceleration or parking functions.

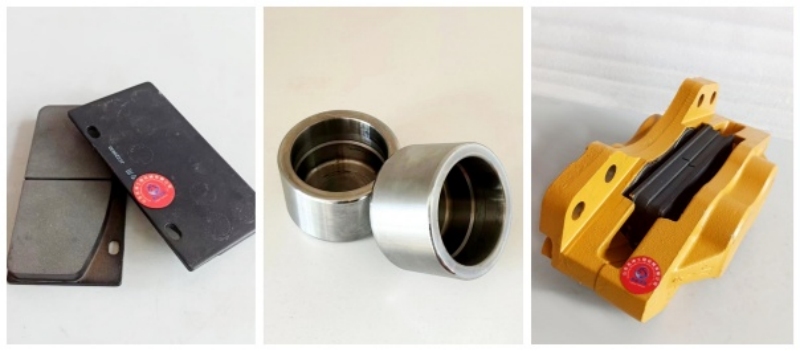

The brake caliper consists of a brake piston, brake pads, bolts, caliper body, etc.

Advantage

1. Stable braking force: Suitable for the braking requirements of a 3-ton loader, the braking torque is precise and controllable, and the wheels can be quickly locked during emergency braking.

2. Wear resistant and wear-resistant: Made of high-grade alloy steel, the friction plate is made of wear-resistant composite materials, which extends the service time under continuous operating conditions.

3. Temperature resistance and anti-aging: It can withstand working temperatures and avoid the risk of brake failure in high-temperature environments.

4. Low noise and smoothness: There is no shaking or abnormal noise during the braking process, and the operating noise is low, improving the comfort of the working environment.

Performance

1. Ensure job safety: achieve smooth deceleration and emergency braking of the loader to prevent the risk of loss of control during operation.

2. Improve handling: Linear braking response, combined with the steering and operation actions of the loader, enhances operational accuracy.

3. Extend component life: Uniform distribution of braking force can reduce uneven wear of brake discs and friction pads, and lower overall maintenance costs.

Maintenance Of Brake Calipers

Brake calipers need to be cleaned, inspected, and lubricated regularly. Regularly use specialized cleaning agents and soft brushes to clean the surface dirt of brake calipers, avoid using high-pressure water guns to rinse, and prevent moisture from entering the system and causing rust or damage. Regularly check the thickness of brake pads for cracks or abnormal wear; Check if the fixing bolts are loose and ensure that the tightening torque meets the requirements. Special lubricating grease is used to lubricate the piston, avoiding contact between the grease and the brake pads or discs, ensuring the sensitivity of the braking system.